Testing, inspection & Licensed Certifications (Third Party Inspection)

Load Testing

Overall heavy lifting machines need to be examined annually or every or six months as the case may be to ensure its safe and trouble free use. The proof load testing on a scheduled basis will guarantee safe use and efficient output while minimizing the accidents, unexpected incident, fatalities and heavy cost on accident repairs including production losses. The equipment that are inspected on load testing are Overhead cranes, Hoists, Motor vehicle lift, supporting runner ways, Web slings, Chain blocks, Lifting Equipment’s, Fork lifts, Building cleaning cradles and Passenger lifts etc.

Licensed Certifications (Boilers and Pressure Vessels including Air & Gas Receivers)

Boilers are one of the significant components in the industrial sector for generating energy and the Occupational and Health authorities are very concern in maintaining the boilers as per the standards, guidelines and certifications required by regulations imposed in this regard. The inspections should be carried out by the third party inspectors and all critical points must be checked during inspections. Boiler should contain its heating surface almost at right angle to current hot gasses for good heat transfer. Also, boiler must have capability to get started rapidly from cold. Further boiler must contain a constant and through flow of water. It must be equipped with all required mountings.

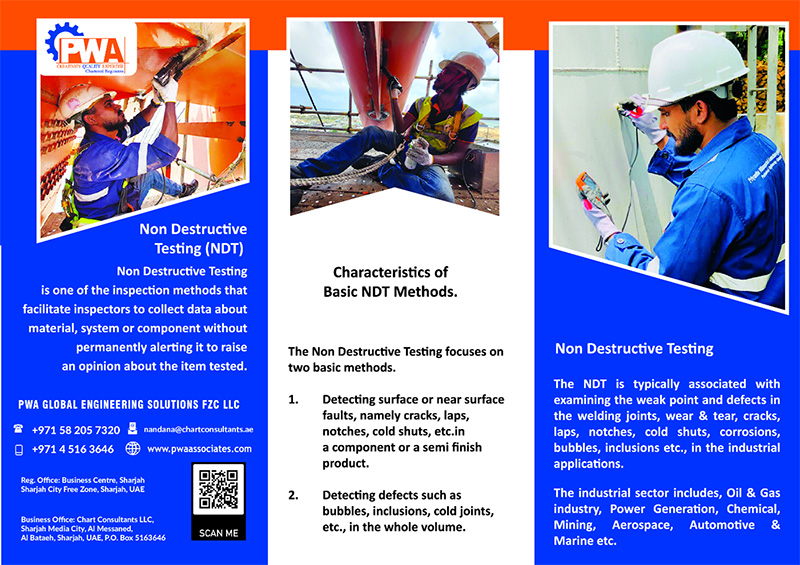

Non Destructive Testing

Non Destructive Testing (NDT) is an engineering science based profession that require competent engineering technicians to inspect materials, welds, components and plants to verify their integrity without rendering them unfit for further service. Depending on the item, component or the plant to be tested on NDT, the following methodologies will be selected to do the best.

• Visual NDT

• Leak Testing NDT

• Ultra Sonic NDT

• Eddy Current NDT

• Radiography NDT

• Liquid Penetrant NDT

• Magnetic Particle NDT

• Acoustic Emission NDT

The following important points of the NDT have been explained in the below chart.

• The importance of NDT

• The characteristics of NDT methods.

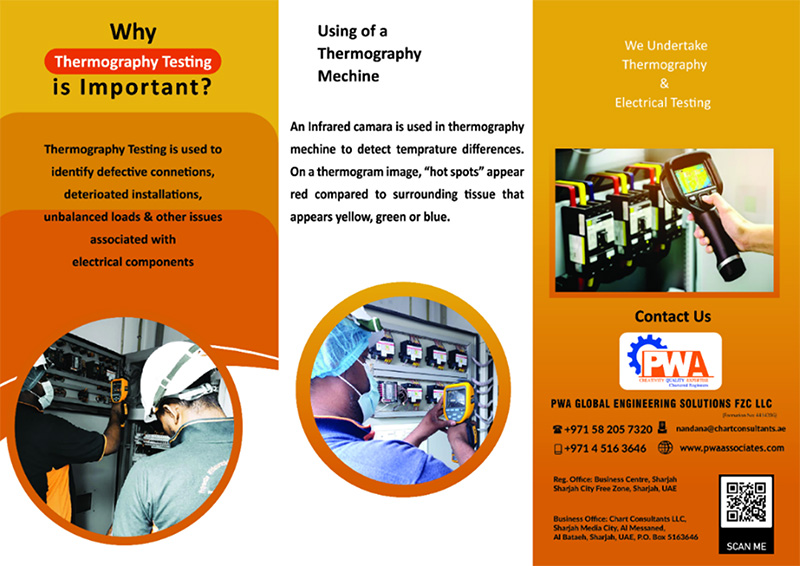

Thermography Testing

Thermography testing is known as infrared inspection and is used to identify the areas of excess heat in the elzectrical installations. While detecting excess heat in advance such issues could be identified early and take corrective actions to minimize damages to the electrical system. In this process, defective connections, deteriorated installations, unbalanced loads and other issues associated with electrical components are identified by using thermography machine. Not only in the industrial sector, the domestic buildings also, caught on fire due to electrical heat and causing heavy damages. In the industrial sector, in addition to the property damages, the production losses too, are incurring until the damages are repaired and production is commenced. Hence, it is paramount to detect electrical system defect early and the answer is to carry out thermography testing on regular intervals.

Electrical Testing

In addition to the thermography testing, the following testing on electrical circuits and electrical power quality issues are undertaken by us for the certification and corrective actions.

• Insulation testing on cables

• Earth loop impedance test

• Soil resistivity test

• Earth electrode test

• Breaker coordination test

• PE connectivity test

• Transformer testing

• Earth discrimination analysis

Apart from the above testing, we are attending to the electrical power quality issues.

• Electrical power sag

• Voltage fluctuations

• Harmonic distortion

• Internal power failures

Be aware of the electrical hazard and take precautions.

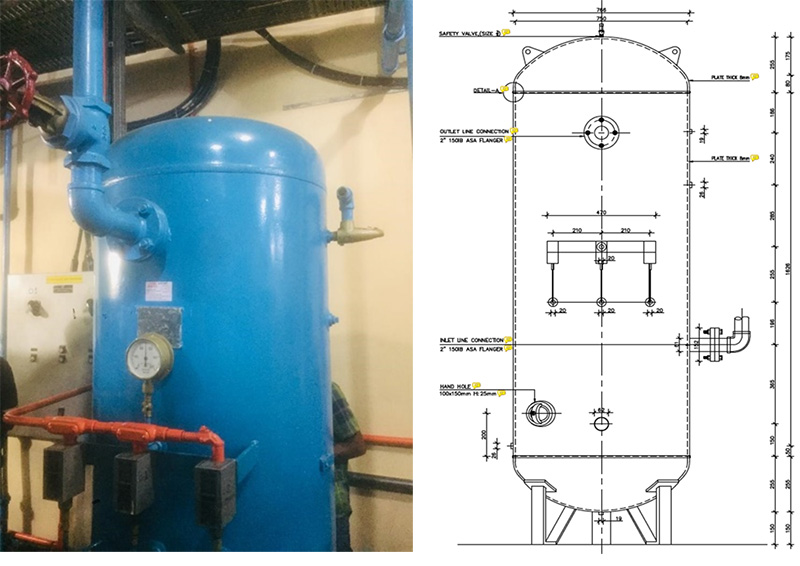

Engineering designs

The organizations those who are dealing with storing liquids and gases need to have specific types of tanks required for their purpose and the major factors in designing the tanks are –

• Design & Configuration

• Manufacturing process

• Coating

• Tank construction

• Maintenance

• Flexibility

• Expandability

We undertake designing tanks and other structures on client’s requirements and their specifications.

Not only engineering designing, we undertake designing and fabrications of specific tools and attachments for the clients to satisfy their requirements. Many industries suffer without having specific tools and attachments to their machinery and equipment’s where such tools or attachments are not readily available in the open market. In these circumstances, the organizations are helpless and wait for their overseas supplies to design and fabricate such tools and attachments and send it back to the client. This process takes a considerable time and the industry is losing their products or services until the matter in question is sorted out. Our engineering team is capable of analyze the issues and design and fabricate tools and attachments needed to operate their products or services efficiently.

Third Party Inspection on Constriction Materials

In the construction sector, industry players need to ensure that their products can withstand certain conditions and comply with increasingly complex national and international building standards and regulations. Therefore, it is essential that all structural materials used in a construction project should be examined to ensure that such structural materials are in conformity with the required national and international standards before using them in the construction process. When employing the internal employees for the examination of construction materials, there are situations where certain actions and behaviors are threatening to the independency and impartiality and therefore, most of the constriction companies are hiring third party inspectors to examine their construction materials. We undertake third party inspection on construction materials at site to ensure that the materials that will be used are in accordance with the project specifications and also, conformity with the national and international standards.

Diversification of our engineering services

Our engineering services have been diversified into many fields and covering the sectors namely, Marine, Aviation and Land.

Marine Sector :

Ports Development Projects

Container Terminal Expansion Projects

On shore/Off Shore Services

Aviation Sector :

Air Port expansion Projects

Engineering inspection and certifications, Aviation Sector

Land Sector :

Detailed Inspection, Operational Testing and Certification for the conformity of a Tower Crane at Housing Development Project

Industrial Training Program conducted by our experts